FlexEnergy Flex GT333S

After review the FlexEnergy Flex GT250S, we continue to discuss the FlexEnergy Flex GT333S.

The Flex Turbine GT333S which is an upgraded generation of the GT250S system, is the most advanced in the industry with up to 85% CHP efficiency and variable inlet guide vanes. One of the main features of the GT333S is that it has fuel flexibility with a smooth transition between natural gas & LPG, certified by the California Air Resources Board (CARB) 2007, capable of a maximum total efficiency of more than 85%. Another feature of the GT333S is that it can be configured with a factory-installed heat recovery module, a third-party WHRU (A waste heat recovery unit) or dual-effect absorption cooler and requires only 8 hours of annual maintenance.

The electrical performance of the GT333S can make electricity efficient with a specification of 33% LHV without a gas booster and the electric power used is 333 Kw. The electrical performance has several special notes including ISO conditions (59°F [15°C], sea level, 60% RH), natural gas pipelines. Electrical efficiency tolerance: +1/-2.5 pts, power tolerance: ± 20kW, elevation drop approx. 3.5% per 1000 ft (305 m), experiences a power reduction of 3 kW when utilizing waste heat recovery (cogeneration).

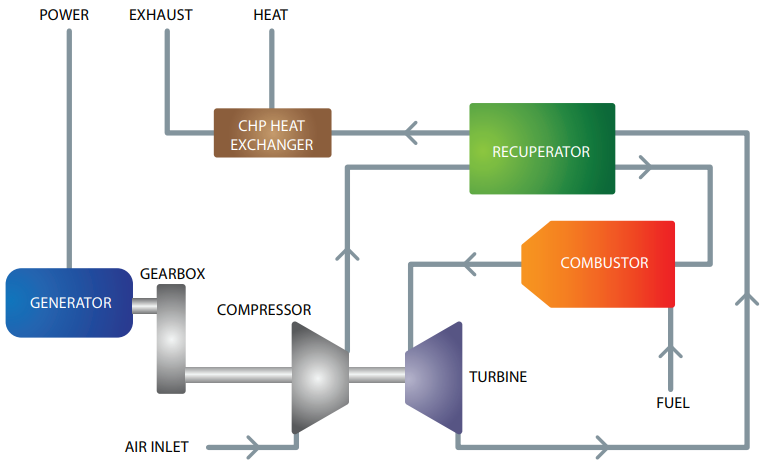

In the rugged gas turbine, the reciprocating component with oil lubricated bearings and a high H?S tolerance of up to 6500 ppmv. The GT333S brake resistor generator measures (W x H x D) 110 x 160 x 78 cm and weighs 595 lb (270 kg). The following is an overview of the Flex Turbine GT333S gas turbine cycle:

Administrator System