Siemens Energy - DATUM ICS

PT Fajar Mas Murni always tries its best to comply with all applicable laws and regulations regarding quality, safety, health and the environment to minimize the impact of environmental pollution. We are committed to maintaining the highest standards of safety and health of all company employees in order to prevent environmental pollution. Perform all activities with proper protection against exposure to hazardous materials to the general public, which pose a risk to their safety and health.

Siemens Energy is an energy company formed by part of the former Gas and Power division of the Siemens Group and covers 67% of Siemens Gamesa's shares. Trusting PT Fajar Mas Murni to market their products in Indonesia. Their products are suitable for sweet natural gas service, also designed to handle acidic natural gas, propane, carbon dioxide, air, nitrogen and most other gases.

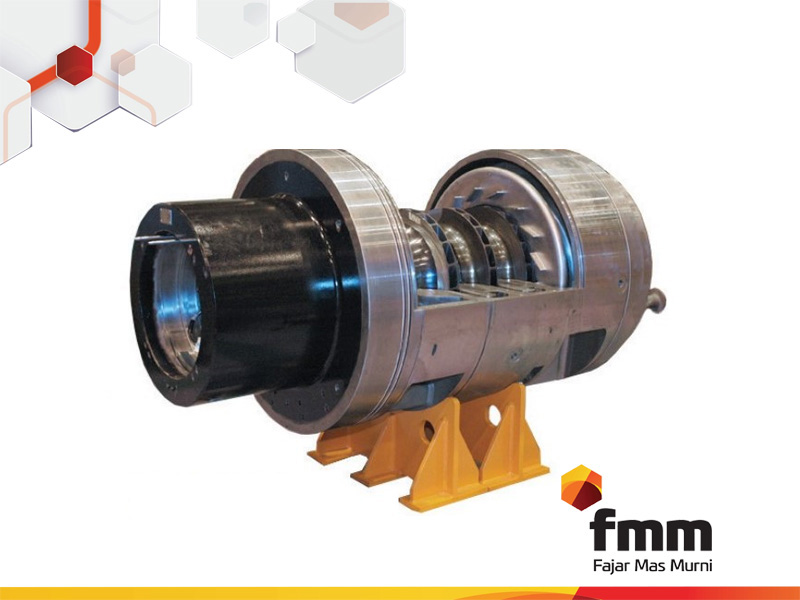

We advertise three types of Siemens Energy Centrifugal Gas Compressors, namely Integrated Compression System, Integral Electric Motor Driven Compressor and DATUM® Centrifugal Compressors. The following product specifications start from the Integrated Compression System. Dresser-Rand developed a new compression concept – the DATUM Integrated Compression System (ICS). The compression system is engineered with centrifugal separator technology incorporated in the compressor rotor to provide an efficient and compact solution for compression system design. DATUM ICS is designed for onshore, offshore and underwater applications.

Versatile and efficient compressor with DATUM ICS system features including high efficiency DATUM centrifugal compressor technology; Dresser-Rand's proprietary centrifugal separation technology; high-speed, gas-cooled, close-paired motor; magnetic bearing rotor system; special unit control; process coolers, valves, instrumentation and interconnect piping – all packaged in a compact module design.

DATUM ICS is a complete compression system applicable to all upstream, midstream and downstream markets with a small footprint, reduced weight and lowest total cost. Each DATUM ICS integrated compression system is factory tested requiring only a short install and startup time, and production can be started faster than with traditional modules.

The DATUM ICS system performs competitively by incorporating Dresser-Rand's proprietary centrifugal separation technology in the compressor housing to efficiently separate liquids from gas streams. This integrated approach makes the DATUM ICS system competitive with the overall performance of traditional systems when it comes to suction scrubbers and pipe loss.

It has an efficient and compact gas-liquid separation method that uses centrifugal force to separate gas, oil and water from the stream. The separation process protects the compression flow path from potential damage by removing free liquid from the gas stream that could cause subsequent fouling during the compression process. Oil and gas operators benefit from a reduction in the overall size of subsea production facilities, platforms and modules due to the small DATUM ICS compression system.

The development of the DATUM ICS separator / compression product system always follows industry standards in order to support the technology qualification program and is very suitable for operating under the sea. The centrifugal separator provides a motor cooling system with cleaner gases and dryers when compared to other solutions that use process gas as the cooling medium. With higher system reliability which extends intervention intervals and reduces operating costs.

Administrator System